We are looking forward to help you!

Contact us »The penetration test enables us to find fine cracks down to less than 1 µm on the surface of your component. The surface of the component should be smooth, non-porous or absorbent.

With the penetration test, we can display the smallest material separations open towards the surface, e.g. fine cracks down to less than 1 µm on a smooth surface. Under UV A radiation, the trained inspectors thus see the indications of the material separations (defects).

Of course, in addition to the fluorescent penetrant method, we also offer the dye penetrant method. Both processes (fluorescent and dye penetrant processes) can also be implemented on your premises.

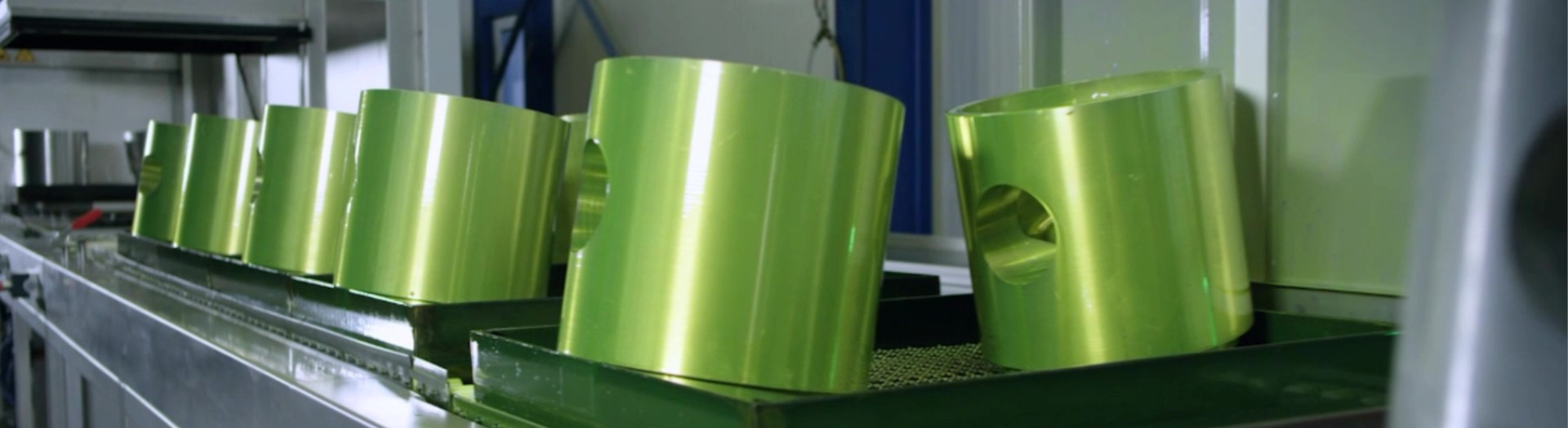

With a large number of semi- and fully automatic systems we have the testing capacity for large quantities (serial parts). In addition, the BMB is exclusively approved for testing components from the automotive and aviation industries, but also from racing and the track.

With the penetration test, all material separations open towards the surface can be displayed.

Material separations with large openings, opening widths from approx. 3 mm and no corresponding depth, may be washed out during intermediate cleaning and can therefore not be displayed. These can only be reliably detected by means of a visual inspection (VT) under appropriate VT light conditions (no UV light).

For this purpose we offer computer tomography.

The penetrant methods (fluorescent and dye penetrant methods) are location-independent and can be used quickly and flexibly both for individual part testing, e.g. of welding seams, and for large quantities to determine material separations over the entire surface to be tested.

Take advantage of our training offer