We are looking forward to help you!

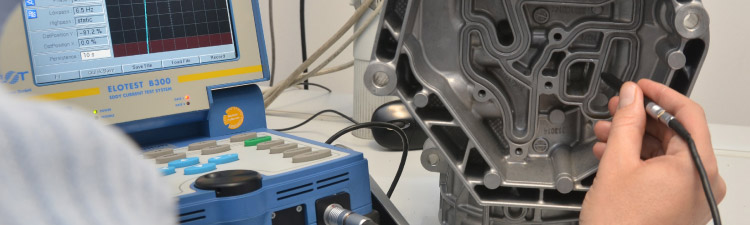

Contact us »Eddy current testing exploits the effect that most impurities and damage in an electrically conductive material also have a different electrical conductivity or permeability than the actual base material. Thus, indications on the surface or inhomogeneities near the component surface of an electrically conductive workpiece can be detected.

If a coil subjected to alternating voltage is brought into the vicinity of a metallic or electrically conductive surface, circular, symmetrical eddy currents perpendicular to the magnetic field lines entering the workpiece are generated close to the surface. The eddy currents generate another secondary magnetic field which runs in the opposite direction to the original one and weakens it. A surface crack or material inhomogeneity forces the eddy currents to take a detour and weakens them. The damage- or material-specific reaction of the eddy currents to the generated secondary magnetic field can be measured by means of problem-adapted coil systems.

The depth determination of individual displays found during the penetration test helps the customer to get a feel for the spread of the display in the component.